-40%

ZENA 1/8" NO-Gas All Aluminum Arc Welding Rods

$ 10.53

- Description

- Size Guide

Description

ZENA®

NO-Gas

tm

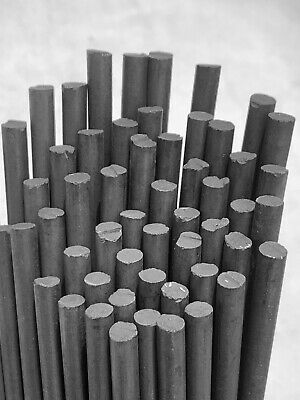

1/8" All Aluminum Arc Welding Rods

Use Your DC Arc Welder to Weld Aluminum!

SquareTrade © AP6.0

Now you can weld aluminum anywhere you can arc weld, even in poor conditions, without the need for a MIG or TIG torch, special welding wire, hoses, regulators, or expensive and heavy gas bottles.

These unique aluminum alloy welding rods let you use your DC arc welder (will not work with AC arc welders) to weld and fill all cast, wrought and extruded aluminum and aluminum alloys, working in all positions, with a high quality high tensile strength (34,000 lb. / 18% elongation) aluminum alloy using only your DC arc welder!

They can also be used with a conventional oxyacetylene torch for gas welding aluminum!

These special aluminum welding rods are perfect for welding, repairing cracks, and building up missing sections of:

Aluminum sheet metal

Truck beds, bodies, and frames,

Loading ramps and docks,

Engine and motor blocks,

Machine bases and supports,

Pipe railings, banisters, stairs, diamond plate,

Transmission housings and gear boxes,

Irrigation piping,

Bus bars, electrical switch boxes and mounts.

Description:

Highly versatile, smooth running, easy-to-handle, all position Aluminum alloy arc/torch welding electrode for welding or filling low alloy Aluminum including Aluminums alloyed with copper, silicon, and magnesium. Also excellent for joining dissimilar grades of Aluminum

Mechanical Properties:

Tensile Strength

(psi & N/mm

2

)

Yield Strength

(psi & N/mm

2

)

Elongation

34,000 psi

(250 N/mm

2

)

20,000 psi (150 N/mm

2

)

18%

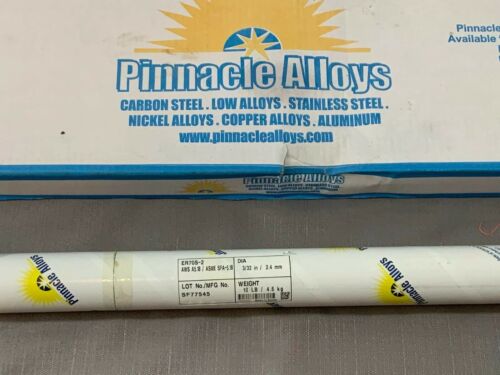

Current Type/Polarity:

DC reverse polarity (electrode positive) -- NOT FOR USE WITH AC ARC WELDERS

Recommended Amperage:

Rod Diameter

1/8" (3.25 mm)

Minimum Amperage

70

Maximum Amperage

120

Rod Diameter:

1/8" (14 rods per 1/2 lb.)

Product Features:

Universal electrode for arc welding all cast, wrought and extruded aluminum and aluminum alloys in all positions.

Also excellent for joining dissimilar grades of Aluminum and Aluminums alloyed with copper, silicon, and magnesium.

Typical Applications:

Truck body/frame repair/fabrication

Cafeteria equipment repair/fabrication

Loading ramps/dock repair/fabrication

Engine and motor blocks/cylinder head repair

Repair and fabrication of machine bases and supports

Repair and fabrication of pipe railings, banisters, stairs, diamond plate

Transmission housings and gear box repair/fabrication

Repair and fabrication of irrigation piping, mixers, paddles, vats,

Repair and fabrication of electrical bus bars, electrical switch boxes. and mounts

Recommended Welding Techniques:

OK for welding in flat, horizontal and vertical applications.

Clean weld area by removing oil and grease and by wire brushing and/or sanding/grinding the immediate weld area just prior to welding. Chamfer edges of plated to be joined and open up/chamfer cracks and/or holes to be filled. Preheat heavy sections broadly. In thick to thin joining, preheat heavier member. For multi-pass work, it might be necessary to reduce amperage setting as base metal increases in temperature.

A close arc should be maintained. Feed electrode quickly and move fast. When picking up each bead, weld into the previous crater before continuing.

Upon cooling, slag/flux can easily be removed by chipping/brushing/sanding/grinding.

Expect best results using motor driven welding equipment with generators with DC rectified DC output.

Not for use with AC Arc Welders

Packaging:

1/8" 1/2 lb. box (14 rods)

Larger packs/quantities and different rod sizes available as special order items.

ZENA

and NO-Gas are trademarks owned by ZENA, Inc. for its welding systems and related products.

©

Copyright 2004 by ZENA, Incorporated. All rights reserved.

NOTE: These rods will work with engine driven welders made by Miller, Lincoln, Hobart, Century, Esab, HTP, Mitsubishi, Thermal Arc, and other companies. When comparing rod specifications, you will find that they function well with ZENA 150A and 200A welders which are comparable to, and will do the same job as, for example, a Miller 225 Bobcat welder, a Hobart 250A welder, a Century 200A welder, or a Lincoln Ranger 8 welder. Of course, 160A, 175A, 180A, 275A, or even 300A, or 400A welders would be also in the same category. MIG and TIG torches made by companies like Tweco and Forney are also compatible with this technology.

NOTE2: In addition to service trucks (particularly popular are Ford Chevrolet and Dodge Diesels) and all types of 4x4's (including Jeep, International, and Toyota), these rods can also be used with all types of heavy equipment, including backhoes, front end loaders, track loaders, forklifts, and tractors as well as all types of utility vehicle.